Rumo Décaplaser

Revendeur exclusif NetaluxNettoyage industriel au laser

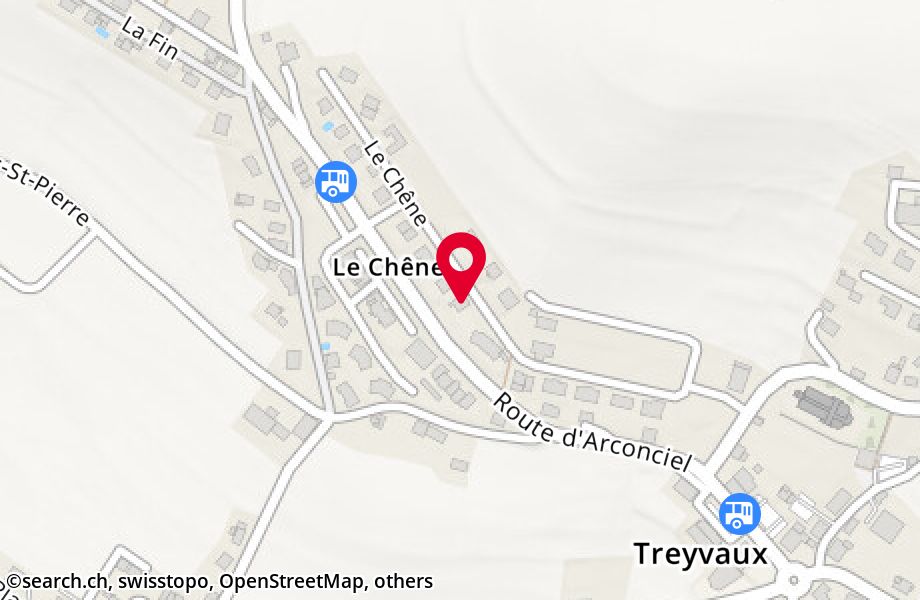

Le Chêne 48

1733 Treyvaux FR

1733 Treyvaux FR

Contacts

| Portable | 079 699 40 35 * |

| Link | www.rumo-decaplaser.ch |

| Link | www.netalux.com |

| Social Media | |

| * No advertising material |

Information

We offer a laser stripping service, an ecological innovation for cleaning your surfaces.

We are the exclusive reseller in Switzerland of the Netalux brand of laser stripping equipment.

How does it work?

- Laser cleaning is a versatile and flexible technology that allows for very precise cleaning without secondary waste, consumables or air movements.

- Removes oxides before and after welding, without chemicals or contaminants. Laser cleaning also helps prepare the weld and significantly reduces the number of imperfections in the weld.

- Removes oxides and coatings from your gates, metal parts and mechanical parts without damaging the substrate.

- Safe cleaning of your valuable moulds. No secondary waste or substrate damage - safe for high gloss finishes and base materials such as aluminium, steel or Ampco alloys.

- Removal of product residues such as silicone, grease, ...

- Copper is one of the many materials that are excellent for laser cleaning. Depending on the form of pulse used, the cleaning can reach different depths.

- Although we prefer metals, it can be almost anything. As long as it can withstand the heat and has some reflectivity.

Contact us for a test on your surfaces.

Translated with www.DeepL.com/Translator (free version)

Web pages

treyvauxservices.ch/project/rumo-decaplaser

treyvauxservices.ch/project/rumo- decaplaser

treyvauxservices.ch/project/rumo- decaplaser

Accueil Inscription Sélectionner une page Rumo Decaplaser Nous offrons un service de nettoyage/décapage au moyen de la technologie laser, …