Closed until tomorrow 07:30

ifm electronic ag

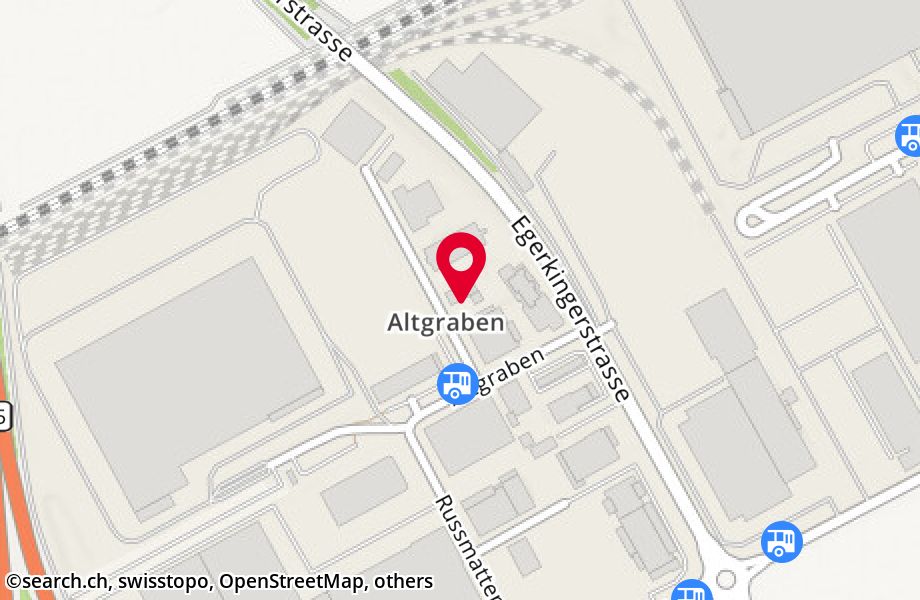

Sensoren & Sensorlösungen4624 Härkingen SO

Photos

Contacts

| Phone | 062 388 80 30 * |

| Link | www.ifm.com/ch |

| Social Media | |

| * No advertising material |

Information

About us

In addition to position and process sensors, sensors for motion control and safety technology are part of the product range. Furthermore ifm offers products for industrial imaging and communication as well as identification systems and systems for mobile machines.

Automation technology and building automation, water / wastewater technology, biogas plants, automotive industry, food, beverage and tobacco industry, building automation, swimming pool technology, water / wastewater treatment, energy generation, mechanical engineering, conveyor technology and logistics

Position sensors Inductive Capacitive Photoelectric Magnetic Cylinder sensors Object detection Evaluation systems Power supplies Encoders Vision Fluid sensors Diagnostic systems You will find all the systems you need at our company.

Products, services

Hygienic flow meter SM Foodmag

In the food and beverage industry, strict hygiene standards and harsh operating conditions are essential to ensure product quality and consumer safety. The sensors used must be able to withstand a wide range of media, high temperatures and temperature fluctuations as well as frequent cleaning cycles, in order to ensure smooth operation and reliable processes.

Discover the new SM Foodmag flow meter that has been specially developed for the food industry.

https://www.ifm.com/ch/en/shared/technologies/flow-sensors/innovations/smf/foodmag-flow-sensor

Flush pressure sensor PL15

Wherever viscous media such as adhesives, glue or sealants are conveyed through pipes under exact and high pressure, the compact G1/2 pressure transmitter PL15 is the ideal choice.

SU Puresonic

The SU Puresonic ultrasonic sensor detects flows of conductive and non-conductive media with high precision. Water, glycol mixtures, coolants, oils and edible oils are all detected with equal reliability.

https://www.ifm.com/ch/en/shared/productnews/2024/launch-09/the-su-puresonic-ultrasonic-sensor

Vibration sensor VVB3

The VVB30x continuously detects the vibrations in three measurement axes and uses them to calculate proven indicators for evaluating the machine condition. This provides the user with information on fatigue (v-RMS), mechanical friction (a-RMS), impacts (a-Peak) and bearing wear (Crest). The surface temperature is also transmitted as an additional wear indicator.

https://www.ifm.com/ch/en/shared/productnews/2024/sps/vvb-as-3-axis-vibration-sensor-with-io-link

Web pages

www.kunststoff- schweiz.ch/html/ifm_electronic_ag.html

www.lebensmittelkatalog.ch/qualitaetssicherung- analytik- messtechnik...

waisch.ch/hashtag/sensorik